Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

source:Han's Photonics

keywords:

Time:2025-12-31

Source: Han's Photonics 24th Dec 2025

Amid the tide of rapid iteration in laser welding technology, technological upgrading has become an irreversible trend. On one hand, the demand for welding precision, efficiency and stability in the high-end manufacturing sector keeps rising, while traditional welding processes struggle to meet the precision manufacturing requirements of industries such as new energy and high-end equipment. On the other hand, the widespread adoption of green production concepts is driving the transformation of welding technology toward automation, intelligence and cleanliness.

based on profound insights into industry trends and solid technological accumulation, at the start of 2026, the Guangdong Laser Industry Association and Shenzhen Laser Intelligent Manufacturing Industry Association, jointly with Shenzhen Han's Photonics Laser Technology Co., Ltd., will host the Greater Bay Area AI + Laser Welding Industrial Summit. The event will bring together top technical experts, seasoned industry practitioners and end-user clients to discuss new trends in technological development and new pathways for industrial upgrading.

Laser Intelligent Welding Empowers Industries

Embark on a New Journey of Technological Innovation

With its inherent technical advantages, laser welding is bound to undergo in-depth upgrading toward the integration of AI perception, intelligent regulation and control, and data traceability, so as to address industry pain points and keep pace with industrial upgrading.

Han's Photonics, which has been deeply committed to the field of intelligent welding, has always been guided by innovation and grounded in technology. From the continuous iteration and upgrading of core products to the constant breakthroughs and innovations in key technologies, from impressive appearances at industry exhibitions to the in-depth expansion of application scenarios, every step of practice fully demonstrates the core strength and industry responsibility of a leader in China's high-end fiber lasers.

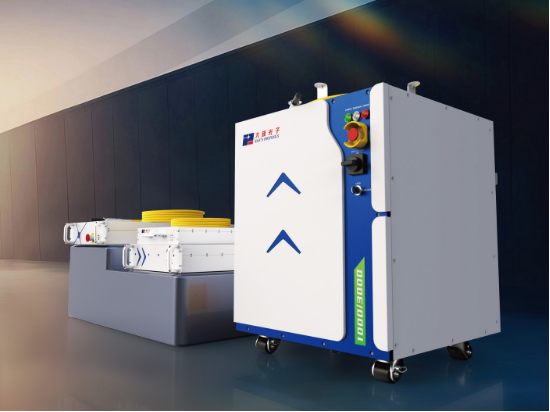

Following the solid and steady development footsteps of Han's Photonics, the company has developed a variety of core products—the "Hanjie" series of high-performance fiber lasers, new energy three-in-one welding systems, the "Tiangong Series" for 3D printing, as well as customized industry application solutions. It has built the most comprehensive product matrix in the industry, fully demonstrating its technical accumulation and innovative achievements in the welding field.

Targeting the pain points of the new energy industry, Han's Photonics has innovatively developed technologies such as ABS anti-spatter technology and single-module integrated systems, achieving an industry breakthrough with a 40% increase in welding efficiency and a product yield of over 99.5%. These technologies have been successfully applied to the mass production lines of leading new energy enterprises.

Break Through Technical Bottlenecks

Innovation-Driven Upgrading of High-End Manufacturing

Han's Photonics has delivered an impressive solution to the long-standing challenge of welding highly reflective materials. In 2025, the company officially launched its Annular Spot Welding Technology, which successfully increased the reliable welding thickness of red copper by more than 50%. This breakthrough has overcome the bottlenecks of insufficient penetration depth and unstable quality associated with traditional processes, providing an efficient solution for the manufacturing of key components such as power batteries and electric drive systems.

In the switchgear manufacturing sector, Han's Photonics' 6000W single-module laser, boasting advantages like high photoelectric conversion efficiency and strong anti-high-reflection capability, has been integrated with an innovative coaxial protection device. This combination has thoroughly addressed the industry pain points of excessive welding spatter, severe smoke pollution and incomplete penetration of long weld seams, enabling high-quality welding.

Focus on Industrial Upgrading: Explore New Opportunities in Intelligent Welding

Committed to deep cultivation and forging ahead with foresight. Against the backdrop of ever-growing demands for welding precision, efficiency, and stability in high-end manufacturing, Han's Photonics, leveraging years of technical accumulation and innovative breakthroughs, has deeply integrated cutting-edge technologies such as AI visual inspection, automated control, and big data analytics into the welding field. It has built a full-process intelligent welding solution, which is comprehensively breaking the efficiency bottlenecks, precision limitations, and quality control challenges of traditional welding processes. This solution enables real-time visual monitoring of welding processes, adaptive optimization of welding parameters, and accurate identification of weld defects, injecting strong impetus into the high-quality development of the manufacturing industry.

Gather Top Minds: Attend the Industry's Annual Grand Event

The global intelligent welding market continues to experience rapid growth in scale, and the Chinese market in particular is showing robust growth momentum, driven by both policy support and industrial demand. Han's Photonics laid out its intelligent welding business layout ahead of the industry curve. Its previously launched new energy three-in-one welding system has integrated the concepts of automation and intelligent control, accumulating rich practical experience for technology implementation. Meanwhile, breakthroughs in core technologies such as annular spot welding have laid a solid foundation for the in-depth development of intelligent welding.

The Greater Bay Area AI + Laser Welding Industrial Summit focuses on the innovative application directions of AI + laser welding, combining technical depth with industrial breadth. It is expected to become a core platform for building a bridge between technology and the market, pooling industry consensus on development, and uniting collaborative synergy. A series of high-profile topics will jointly unlock new opportunities for industrial development and work together to write a new chapter in the high-quality development of the intelligent welding industry. Let us wait and see!

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out 9th Secret Light Awards Launch: Million-Yuan Fund + National Award Recommendation

9th Secret Light Awards Launch: Million-Yuan Fund + National Award Recommendation

Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer

Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

more>>

Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

more>>